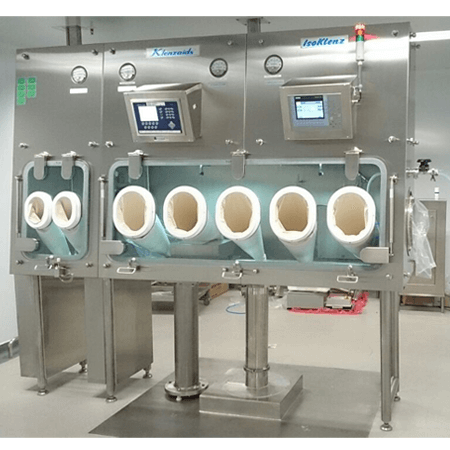

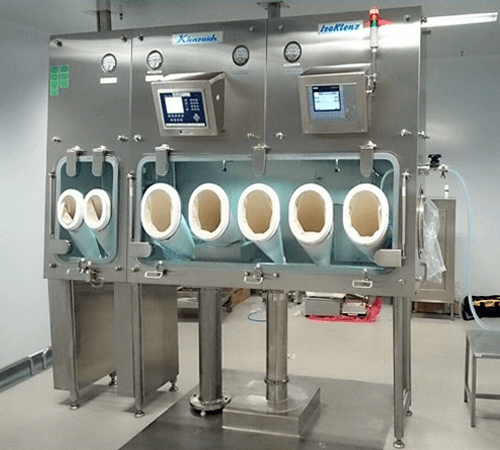

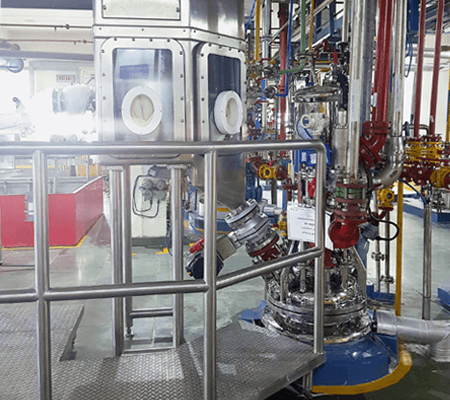

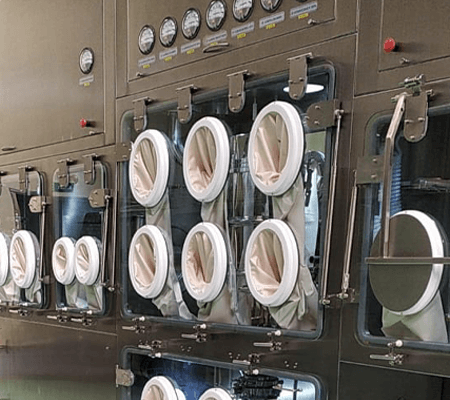

Highly Potent Active Pharmaceutical Ingredients HPAPI facilities are challenging to build, operate and maintain. Each process step although aided by gravity or vacuum is fraught with risks like potency, explosion & product characteristic changes. There is significant use of solvents and chemicals that call for chemical safety levels that in many cases surpass even the most stringent levels. After reaction these molecules need to be filtered, dried, shaped, sifted, micronised, blended and packed with each process step causing exposure of a varying environments. Personnel and product have to be adequately safeguarded. Global environmental authorities such as NIOSH/OSHA have set limits on human and environment exposure for such molecules and their manufacturing process. Klenzaids has spent last 25 years studying and containing these molecules and working with the best HPAPI manufacturing companies in the world.Klenzaids designs and builds IsoKlenz® containment isolators and solutions for APIs right down to the nano level.

KLENZAIDS